1. The engine power is sufficient and the operation is normal, but the machine speed is slow and the excavation is weak

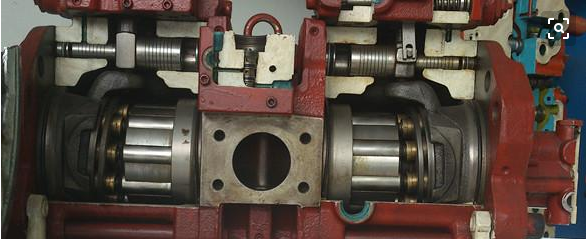

The hydraulic pump of the excavator is a plunger variable pump. After working for a certain period of time, the internal hydraulic components of the pump (cylinder, plunger, distribution plate, nine-hole plate, turtle back, etc.) will inevitably wear excessively, causing a large amount of internal leakage. The parameter data are not coordinated, resulting in insufficient flow, too high oil temperature, slow speed, and inability to establish high pressure, so the movement is slow and the excavation is ineffective. For such problems, the hydraulic pump must be removed and sent to a professional company for debugging. The hydraulic pump must be opened for data measurement to confirm the problem with the excavator. Parts that cannot be used should be replaced, parts that can be used should be repaired, and the hydraulic pump must be reassembled. Finally, go to the import calibration bench for debugging. Just match the soft parameters of each system (pressure, flow, torque, power, etc.).

2. Walking off track, and the movement of one handle is not ideal

Hydraulic pumps are divided into front and rear pumps or left and right pumps. If the walking deviation indicates that one of the pumps is faulty, the simplest way to judge is: swap the two high-pressure oil outlet pipes of the hydraulic pump. If the original slow leg becomes faster, the faster leg becomes faster. If it is slow, it proves that one of the pumps is faulty. For this kind of problem, you need to remove the hydraulic pump, replace the accessories in one pump, and then go to the imported calibration bench for debugging. It also solves the problem of unsatisfactory movement of one handle.

3. The engine power is sufficient, but the car is bored (suffocated)

The hydraulic pump itself also has a certain amount of power. If the hydraulic power is greater than the engine power, the car will be stuck (stuck). This requires debugging the hydraulic pump on the imported calibration bench and reducing the power of the hydraulic pump to 95% of the engine power.

4. When the machine is cold, everything is normal. When the machine is hot, the movement is slow and the excavation is weak

This kind of problem means that the hydraulic pump has reached the point where it must be overhauled. The internal parts of the hydraulic pump are severely worn. Continued use may cause more serious wear of the internal parts of the hydraulic pump. All internal worn parts must be replaced, reassembled and debugged on an imported calibration bench to restore the hydraulic pump to its standard condition.

If your excavator needs excavator accessories such as hydraulic pumps, or if you want to buy excavators and second-hand excavators, you can contact and consult us. ccmie will serve you wholeheartedly.

Post time: Apr-30-2024