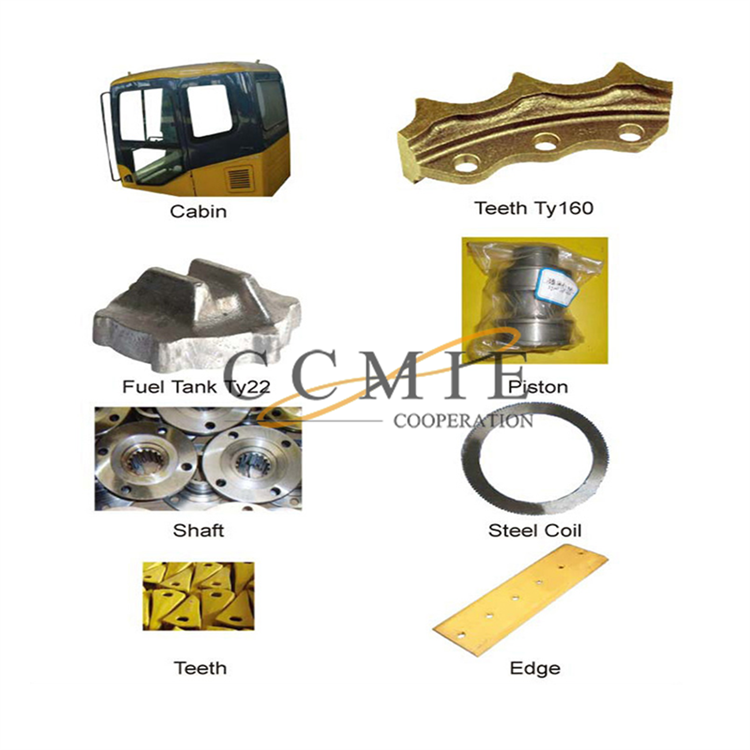

Mining bulldozers play a vital role in mining operations. Their powerful power and efficient operating capacity enable them to quickly complete tasks such as material handling and site leveling. However, ensuring that mining bulldozers are always in optimal working condition requires high-quality, compatible parts. This article will delve into relevant information about mining bulldozer parts to help mining companies achieve efficient and stable production operations.

How to Choose the Right Mining Bulldozer Parts

Confirm the equipment model and specifications: Mining bulldozers of different models and specifications require different compatible parts. When selecting parts, it is important to accurately confirm the equipment model, serial number, and other information to ensure that the selected parts are fully compatible with the equipment. This will avoid equipment failure or performance degradation due to part incompatibility.

Focus on part quality: Quality is a key factor in selecting parts. Prioritize brands and suppliers with a good reputation and relevant quality certifications (such as ISO quality management system certification and mining safety certification). High-quality parts are typically made from high-performance materials and undergo sophisticated processing techniques, resulting in superior strength, wear resistance, and reliability. For example, track shoes made from high-strength alloy steel have a significantly longer service life than those made from standard materials.

Consider cost-effectiveness: While pursuing high-quality parts, it’s also important to consider cost-effectiveness. The most expensive part isn’t necessarily the most suitable. A comprehensive evaluation should be made of factors such as price, quality, service life, and maintenance costs. For critical parts that significantly impact equipment performance, such as core engine components, it’s recommended to choose reliable, high-quality, branded products. While more expensive, these effectively ensure stable equipment operation and reduce overall costs in the long run. For non-critical, easily worn parts, it’s advisable to choose more reasonably priced products while ensuring quality is maintained.

Check after-sales service: Excellent after-sales service provides strong user protection. Choose a supplier that offers comprehensive after-sales service, including warranty coverage, repair support, and technical consulting. If quality issues arise with parts, the supplier will respond promptly and provide solutions, minimizing equipment downtime. Furthermore, the supplier should maintain a sufficient inventory of parts to ensure timely replacement requests.

Reference actual use cases and user reviews: Learn about other mining companies’ actual experiences and evaluations of various brands and models of accessories through online channels, industry forums, and peer-to-peer discussions. Real user feedback helps us more intuitively understand the performance, quality stability, and after-sales service of accessories, allowing us to make more informed choices.

If you need to purchase mining bulldozer accessories or learn more about maintenance, please contact us directly. We will provide you with excellent service and a positive purchasing experience!

For other parts, please provide us with the part number or visit our related websites:

Click here to visit our spare parts web

Click here to visit our alibaba (There are more kinds of products)

Post time: Sep-19-2025