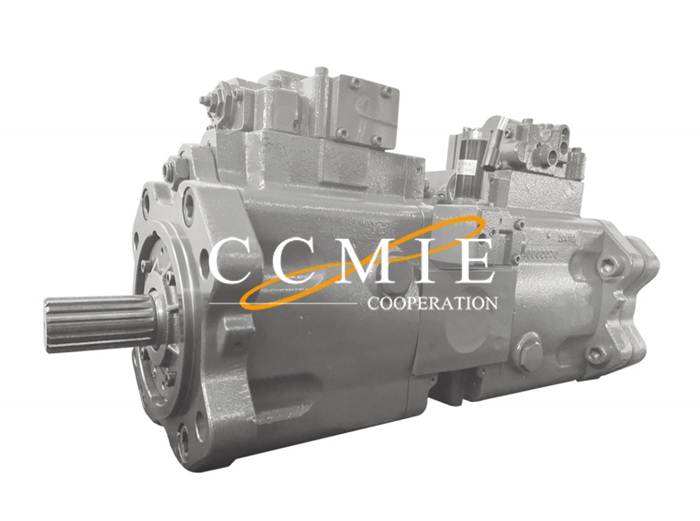

Today, we will do detailed explanation about Komatsu machine pump. This hydraulic pump is actually a kind of plunger pump: Mostly, we use two models in PC300 and PC200. Those two models are 708-2G-00024 and the other is 708-2G-00023

Features of Komatsu excavator hydraulic pump

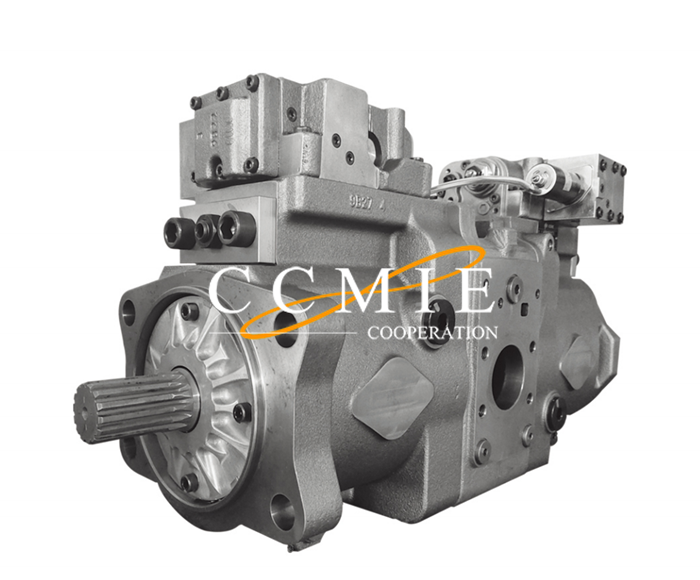

◆Axial plunger variable pump with swash plate structure, specially designed for high-efficiency hydraulic drive of open circuit.

◆ Widely used in ceramic presses, refractory presses, steel and forging presses, metallurgical machinery, mining machinery, marine machinery, petroleum equipment, engineering and machine tool control industries;

◆Displacement specifications: 40, 71, 125, 180, 250, 300, 355, 500, 750 ml/revolution;

◆ With swash plate angle indicator;

◆ Excellent inhalation characteristics;

◆ Sensitive control response;

◆ Specially designed long-life, high-precision aviation-grade full-roller bearings;

◆ Low noise, long life, excellent power and weight ratio;

◆ Through-shaft structure, can be superimposed into a combined pump;

◆ The flow rate of the hydraulic pump is proportional to the speed and displacement of the pump, and the displacement can be adjusted steplessly by adjusting the inclination of the swash plate;

◆ Complete variable forms, commonly used are DR/DRG constant voltage control, LR hyperbolic constant power automatic control, EO2 electrical proportional control;

◆ Rated working pressure can reach 350Bar (35MPa) peak pressure of 420bar (42MPa);

◆ Applicable medium: mineral oil, water glycol, cleanliness requirements NAS9;

What to do if there are stains inside the Komatsu EXCAVATOR HYDRAULIC PUMP

Usually after a period of use of hydraulic pumps, contaminants will appear. When the hydraulic pump is polluted from the outside, it will not only affect the normal operation of the hydraulic pump, but also affect its service life. Do you know how these pollutants are produced? The following editor will take you to find out.

First of all, the original hydraulic pump undergoes multiple processing methods in the production process, and it is inevitable that pollutants will enter it during the processing, transportation, and equipment process. However, we can reduce the production of pollutants during the processing of hydraulic pumps by keeping the environment clean.

In addition, dust and impurities in the air will penetrate into the hydraulic pump through the small pores of the hydraulic pump. After a long time, it will cause the accumulation of dust and affect the use of the hydraulic pump. Therefore, we have to clean the hydraulic pump regularly to ensure the cleanliness of the hydraulic pump system to improve work efficiency. hydraulic pump head has a chute cut on the cylindrical surface and communicates with the top through radial holes and axial holes. The purpose is to change the circulating oil supply; the plunger sleeve is made with oil inlet and return holes, both of which are connected to the pump. The low-pressure oil cavity in the upper body is communicated, and the plunger is inserted into the upper body of the pump, and the positioning screw is used for positioning.

The specific content of daily maintenance can be divided into: operating data records, fault records. Record the operating data of hydraulic pumps and motors every day, including hydraulic pump output frequency, output current, output voltage, internal DC voltage of hydraulic pump, radiator temperature and other parameters, and compare them with reasonable data to facilitate early detection of hidden troubles. .

KOMATSU EXCAVATOR HYDRAULIC PUMP pressure can not rise:

1. The pump is not oiled or the flow is insufficient-the same as the above-mentioned elimination method.

2. The adjustment pressure of the overflow valve is too low or malfunctions-re-adjust the pressure of the overflow valve or repair the overflow valve.

3. Leaks in the system-check the system and repair the leaks.

4. Due to the vibration of the plunger pump for a long time, the pump cover screws are loosened-properly tighten the screws

5. Air leakage in the suction pipe—check all connections, and seal and tighten them.

6. Insufficient oil absorption-same as the elimination method mentioned above.

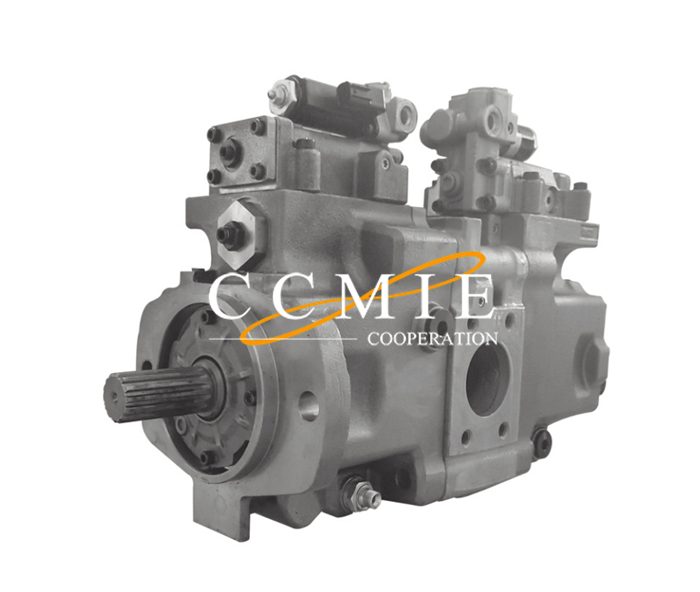

7. Features of variable column KOMATSU EXCAVATOR HYDRAULIC PUMP :

◆Axial plunger variable pump with swash plate structure, specially designed for high-efficiency hydraulic drive of open circuit.

◆ Widely used in ceramic presses, refractory presses, steel and forging presses, metallurgical machinery, mining machinery, marine machinery, petroleum equipment, engineering and machine tool control industries;

◆Displacement specifications: 40, 71, 125, 180, 250, 300, 355, 500, 750 ml/revolution;

◆ With swash plate angle indicator;

◆ Excellent inhalation characteristics;

◆ Sensitive control response;

◆ Specially designed long-life, high-precision aviation-grade full-roller bearings;

◆ Low noise, long life, excellent power and weight ratio;

◆ Through-shaft structure, can be superimposed into a combined pump;

◆ The flow rate of the hydraulic pump is proportional to the speed and displacement of the pump, and the displacement can be adjusted steplessly by adjusting the inclination of the swash plate;

◆ Complete variable forms, commonly used are DR/DRG constant voltage control, LR hyperbolic constant power automatic control, EO2 electrical proportional control;

◆ Rated working pressure can reach 350Bar (35MPa) peak pressure of 420bar (42MPa);

◆ Applicable medium: mineral oil, water glycol, cleanliness requirements NAS9;

What to do if there are stains inside the KOMATSU EXCAVATOR HYDRAULIC PUMP

Usually after a period of use of hydraulic pumps, contaminants will appear. When the hydraulic pump is polluted from the outside, it will not only affect the normal operation of the hydraulic pump, but also affect its service life. Do you know how these pollutants are produced? The following editor will take you to find out.

First of all, the original hydraulic pump undergoes multiple processing methods in the production process, and it is inevitable that pollutants will enter it during processing, transportation, and equipment. However, we can reduce the production of pollutants during the processing of hydraulic pumps by keeping the environment clean.

In addition, the dust and impurities in the air will penetrate into the hydraulic pump through the small pores of the hydraulic pump. After a long time, it will cause the accumulation of dust and affect the use of the hydraulic pump. Therefore, we have to clean the hydraulic pump regularly to ensure the cleanliness of the hydraulic pump system to improve work efficiency. hydraulic pump head has a chute cut on the cylindrical surface and communicates with the top through radial holes and axial holes. The purpose is to change the circulating oil supply; the plunger sleeve is made with oil inlet and return holes, both of which are connected to the pump. The low-pressure oil cavity in the upper body is communicated, and the plunger is inserted into the upper body of the pump, and the positioning screw is used for positioning.

The specific content of daily maintenance can be divided into: operating data records, fault records. Record the operating data of hydraulic pumps and motors every day, including the output frequency, output current, output voltage of hydraulic pumps, internal DC voltage of hydraulic pumps, radiator temperature and other parameters, and compare them with reasonable data to facilitate early detection of hidden troubles.

KOMATSU EXCAVATOR HYDRAULIC PUMP pressure can not rise:

1. The hydraulic pump is not oiled or the flow is insufficient-the same as the above-mentioned elimination method.

2. The adjustment pressure of the overflow valve is too low or malfunctions-re-adjust the pressure of the overflow valve or repair the overflow valve.

3. Leaks in the system-check the system and repair the leaks.

4. Due to the vibration of the Komatsu plunger pump for a long time, the pump cover screws are loosened-properly tighten the screws

5. Air leakage in the suction pipe—check all connections, and seal and tighten them.

6. Insufficient oil absorption-same as the elimination method mentioned above.

7. Improper adjustment of variable plunger pump pressure-readjust to the required level. The pressure of the Sauer 45 series plunger pump is improperly adjusted-readjust to the required level. Sao 45 series plunger pump

Post time: Nov-17-2021