Applying the brakes is a familiar action in daily driving. In most cases, the brake pedal is more important than the clutch or accelerator pedal. Some people often experience brake jitter when applying the brakes. While the brakes can stop, it can be a cause for concern. The previous two articles discussed the causes of brake pads and drums. This article focuses on the third, slightly less common, cause of brake jitter: unauthorized brake modification.

Reason 3 for brake jitter: Unauthorized brake modification. Excessive pressure causes the wheel cylinder to operate out of sync

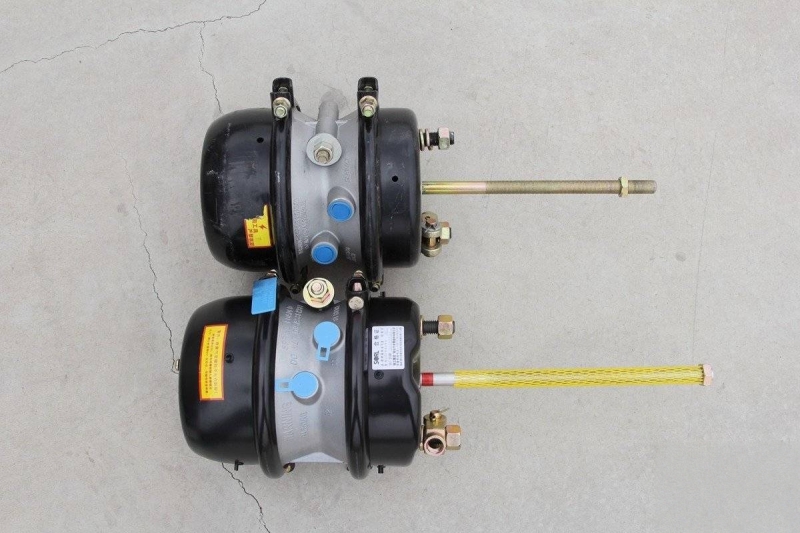

We all know that the main function of the brake wheel cylinder is to apply air to the brake shoes, thereby applying the brakes. As a key component in the braking system, the brake wheel cylinder plays a vital role.

However, many drivers nowadays, seeking better braking performance and faster response times, install a relay valve with increased air volume. The benefit of increased air volume is that air can pass through the brake wheel cylinder, applying greater thrust to the brake shoes, resulting in faster and more powerful braking.

On the surface, this modification may seem seamless, but blindly increasing the air volume in pursuit of better braking performance can actually disrupt the original vehicle’s balance. First, the brake pads and drums are designed based on the original vehicle’s air pressure. Constant use of high air pressure to push the wheel cylinder can cause abnormal wear on the drums and pads, leading to brake judder and component damage at best, and even worse, shoe burns, drum cracks, and brake system failure.

Furthermore, increasing the air volume of the relay valve can cause an imbalance in the air pressure between the two wheel cylinders, leading to asynchronous operation. One wheel cylinder may have too much air pressure while the other has too little. Even when the brakes are applied, there’s a noticeable difference in braking force between the two wheels, which can also cause brake judder.

So, whether you’re using a trailer or the main vehicle, avoid reckless modifications simply to achieve shorter braking distances and faster response. Modified brakes will subject the wheel cylinder, pads, and drums to greater pressure than before, significantly increasing the risk of component damage and loss of control.

In addition to the aforementioned causes, there are other potential causes of brake judder, such as out-of-round tires or wheels. During braking, the vehicle’s center of gravity shifts toward the out-of-round wheel. Excessive play between the steering ball joint and the vertical shaft can also cause vibration during braking. However, by determining the location and magnitude of the vibration, many service station technicians can easily determine the general cause.

Although brake judder may seem like a minor issue, both OEMs and service stations are diligently investigating abnormal vehicle judder during vehicle design and development, as well as during ongoing maintenance. If your vehicle experiences brake judder, be sure to contact a service station immediately to thoroughly resolve the cause and avoid further complications.

If you need to replace or purchase spare parts for your truck during routine maintenance, please contact us! We offer a wide range of construction machinery products and spare parts, so please feel free to inquire!

Click here to visit our spare parts web

Click here to visit our alibaba (There are more kinds of products)

Post time: Jul-29-2025