The bulldozer tracks are all connected by dozens of track shoes, chain track sections, track pins, pin sleeves, dust rings and track bolts of the same shape. Although the above-mentioned parts are made of high-quality alloy steel and made by heat treatment, they have good wear resistance and impact resistance. However, because the weight of bulldozers is more than 20 to 30 tons, the working conditions are very harsh, and they are often It is easy to wear when driving on rocky, muddy, or even salt-alkali and marsh areas. Therefore, correct maintenance and use are necessary to extend the service life of the crawler assembly. Below we briefly share some precautions in the maintenance and use of the crawler.

1. Frequently check and adjust the tightness of the track. During the inspection, the vehicle should be parked on a flat place, and then parked naturally (without brakes) after moving forward for a while, and measure the size with a straightedge on the grouser between the supporting wheel and the guide wheel. Measure the gap C according to the diagram method, generally C=20~30mm is appropriate. Note that the sag of the left and right crawlers should be the same. When the machine is working in a flat and hard area, it should be tightened; when it is working in a clay or soft area, it should be adjusted to be looser.

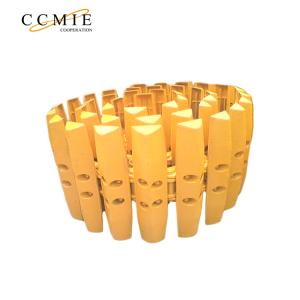

2. After the tooth block on the sprocket is worn to the allowable size, it should be replaced in a complete set in time.

3. Be gentle when driving the machine. Do not rush and bump when working in uneven areas. Do not turn at high speed or turn in place during driving. Do not turn sharply when reversing to prevent damage to the track or derailment.

4. When the track is found to be bounced, tight, jammed or abnormal noise is heard during the operation, the machine should be shut down immediately for investigation.

5. Do not overload work in uneven or inclined left and right areas, so as to prevent the machine from being unable to move forward and causing the crawler to spin at high speed in situ, causing rapid wear and tear on the components of the walking system.

6. When the machine passes through a railway crossing, the driving direction should be perpendicular to the rail, and it is not allowed to change speed, stop or reverse on the rail to prevent the track from getting stuck in the rail and causing a major traffic accident.

7. After the work is completed, the sludge, entangled weeds or iron wires should be removed from the track; check whether the track pin is moving or loose, whether the track section is cracked, whether the track shoe is damaged, if necessary Perform welding repair or replacement.

Post time: Jul-28-2021