Good Quality Xcmg Concrete Pump Spare Parts - floating oil seal for concrete pump spare parts – CCMIE

Good Quality Xcmg Concrete Pump Spare Parts - floating oil seal for concrete pump spare parts – CCMIE Detail:

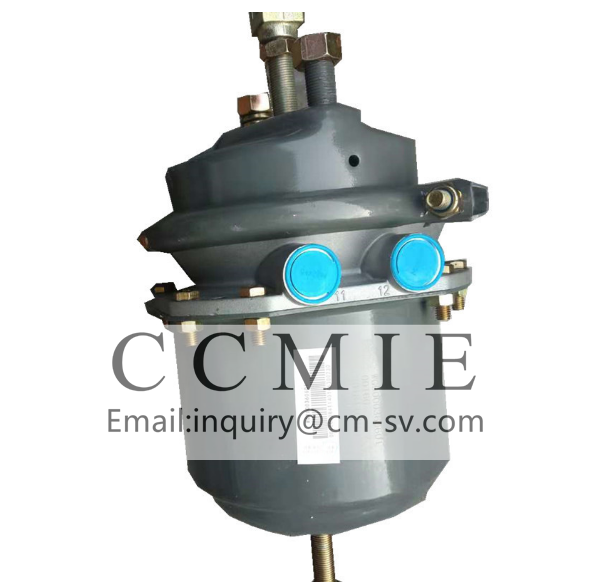

floating oil seal

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones

advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

Packing

Carton Boxes, or according to clients’ request.

description

Floating oil seal is a special type of mechanical seal. It is a compact mechanical seal method developed to adapt to the harsh working environment. It has strong anti-pollution ability, wear resistance, impact resistance, reliable work, and automatic end face wear. The advantages of compensation and simple structure are the most common applications in construction machinery products, and are also widely used in various conveyors, sand processing equipment, and concrete equipment. In coal mining machinery, it is mainly used for the sprocket of the scraper conveyor, the speed reducer and the transmission mechanism, rocker arm, drum, etc. of the coal shearer. This kind of sealing products are more common and mature in construction machinery and equipment, but in other industries, due to the small amount of use, the lack of basic theoretical data and use experience, the failure phenomenon is more common during use, and it is difficult to achieve the expected results.

Structure principle

The floating oil seal is composed of two identical metal rings and two rubber rings. Its working principle is that a pair of rubber rings form a closed space with the cavity under the support of the metal ring (but not in contact with the shaft). The metal ring is rotating. The two grinded surfaces of the machine are closely matched and slide relatively, on the one hand to ensure good operation, on the other hand, to effectively seal off external dust, water, sludge, etc., to protect the internal lubricating grease from leaking.

The sealing principle of the floating oil seal is that the two floating rings are deformed by the axial compression of the O-shaped sealing ring to produce a pressing force on the sealing end face of the floating ring. With the uniform wear of the sealing end face, this elastic energy stored by the O-ring seal is gradually released, thereby playing an axial compensation role. The sealing surface can maintain a good fit within the set time, and the general sealing life is more than 4000h.

our warehouse

Pack and ship

Product detail pictures:

Related Product Guide:

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of Good Quality Xcmg Concrete Pump Spare Parts - floating oil seal for concrete pump spare parts – CCMIE , The product will supply to all over the world, such as: Hanover, Barbados, Malaysia, We pay high attention to customer service, and cherish every customer. We have maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!